Hexapod now has 18 working servos again! yay.

Servo Failure modes

I didn’t strip the gears* on one of my servos from applying to much load to it (the way I expected my servo to fail), but rather stripped the threads on the servo to servo horn coupler.

*see http://techtv.mit.edu/videos/10523-what-is-design-an-example for a good video of designing a robot, having the gears strip, and solving that problem with rubber “shock absorbers.” This video is shown near the very beginning of 2.007 Design and Manufacturing I, a sophomore build-robots mechanical engineering class.

$9.98 for 2, or $4.99 each.

Probably I paid way too much but whatever. At the time I thought $5 was really cheap for a servo (now I think $3 is more reasonable price for this servo). Bought 2/9 and delivered 2/19, not bad.

|

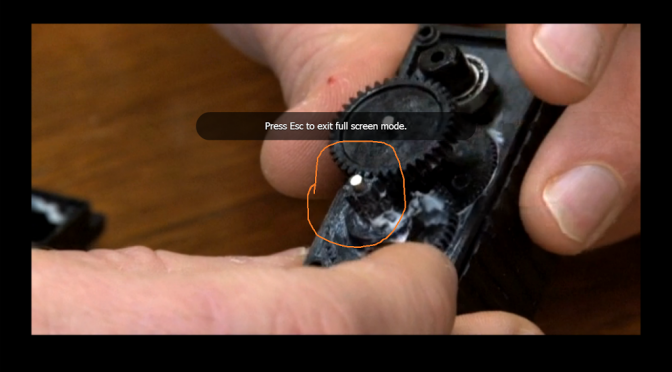

| left: 4-40 screw mates fine with servo horn. top: a 4-40 tap. right: A proprietary screw with mysterious thread count and pitch next to a nylon 4-40 screw. |