|

| thanks Jamison (http://thevariableconstant.blogspot.com/) for the picture! |

Here it is, just finished at MITERS and still tethered to a power supply. Later I electrical taped on a lipo battery, I kid you not.

From the front it looks normal, which is unfortunate for the graduation video, but whatever, I tried.

Only if you get some height above me can you see the lights.

|

| what it looks like from the side. yea I can’t believe it got through security too, especially after Jordan‘s kawaiicopter cap that she worked on all winter break was rejected :'( |

The original plan was to have a spinning RGB POV display, ala the plenitude of persistence of vision clock displays out there.

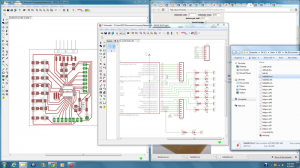

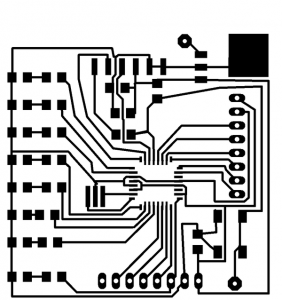

I even milled out a board for it, based on the fabduino files.

|

| cute non-RGB 7 LED pov board |

I can upload the eagle files if anyone wants, but since I haven’t gotten it to work and I can’t be sure there’s nothing wrong with the circuit I don’t want to put the effort into putting it up. This was my first exploration of the autoroute tool, which seemed to work pretty well.

Anyway after pulling two almost-all-nighters working on that project, I gave up when I couldn’t get the arduino bootloader burned onto the atmega (couldn’t get it to program at all, actually — hit a Target not found error). The cap I actually ended wearing was very simple to make and took about 6 hours total, including time spent trying to waterproof it with hot glue and saran wrap. (Most of the letters are stuck on there with the original backing tape that came on the strip). I didn’t have black wires so I used thick brown but still single core wire. I also probably should have done a 6 LED strip for the “I” and just covered up the center portion with electrical tape. Instead, I just skipped the dot on top of the “i”.

I also found this tool supppeerr useful, way more useful than the helping hands, for holding thick and relatively unyielding wires together so that I could solder them:

|

| src: http://www.orangenarwhals.com/wp-content/uploads/2013/06/il_340x270.329862126-300×238.jpg http://www.etsy.com/market/surgeon_tools?ref=listing_tag |

If you look carefully there are also two burn marks on my cap. I just colored the cardboard underneath with sharpie.

I also would have taken off my cap and showed it to the camera as I was coming down the ramp after getting my diploma if I knew how graduation worked.

I should have sanded down all the wires because I think a lot of the joints were cold solder joints (this bit me when I was repositioning the letters), but it worked okay and is probably the most robust of all the projects I’ve done so far because the circuit is encased in hot glue. Sorry arduino mini! (I potted that into the breadboard). The circuit itself is super straightforward, 3 FETs directly driven by the arduino. See http://learn.adafruit.com/rgb-led-strips/overview.

|

| This is what graduation looked like for the parents. |

Graduation itself was simply wet and miserable. I was on-and-off shivering by midway through and the list of names seemed endless. I’m sure they were rushing toward the end.

========================

APPENDIX: Milling circut boards on a Roland modela mill (in the IDC)

========================

Ultimate lesson learned: Make your traces at least 16 mil, 12 mil does not work!

https://github.com/

It’s a 5 LED font.

Pin mapping

http://arduino.cc/en/Hacking/PinMapping168

FTDI headers:

DTR,

How to create board outline in eagle:

http://www.electro-tech-online.com/general-electronics-chat/31558-problem-cad-eagle-how-draw-board-space.html

Eagle MAS.863 documentation

Design rules:

http://academy.cba.mit.edu/2012/labs/providence/tutorials/07.html

http://fab.cba.mit.edu/content/processes/PCB/

http://academy.cba.mit.edu/classes/electronics_design/index.html

5V 1A regulator is in a SOT-223 package

Fab lab inventory

http://fab.cba.mit.edu/about/fab/inv.html

LM2940IMP-5.0CT-ND

http://octopart.com/datasheet/lm2940imp-5.0%2Fnopb-national+semiconductor-1009434-134675

input gnd output

hmm tangent about IC naming (78xx = vreg)

http://blog.screamingcircuits.com/2013/01/more-cautionary-tails.html

Hmmm eagle files for this vreg

https://www.sparkfun.com/products/595

gnd out in, so pin assignments are wrong, should be easy fix

https://github.com/sparkfun/SparkFun-Eagle-Libraries

https://github.com/sparkfun/SparkFun-Eagle-Libraries/blob/master/SparkFun-PowerIC.lbr

MAke sure to download zip file! OTherwise file does not download properly (adds some html comments at the beginning)

Currently the Vreg-LM1117 package is

1 ADJ

3 IN

2 OUT

4 OUT@1

which matches the datasheet https://www.sparkfun.com/datasheets/Components/FAN1117A.pdf 1:GND, 2:OUT, 3:IN.

However for the LM2940 I want

1:IN 2:GND 3:OUT

Steps ish (very incomplete)

Library>Open>Sparkfun-PowerIC

LIbrary>Device>LM1117

Connect> Disconnect all of them

Create new device

Grid dimensions in autorouting:

https://forum.sparkfun.com/viewtopic.php?p=76309

Export dpi?

http://academy.cba.mit.edu/2012/labs/providence/tutorials/07.html

then export as a png (file — export — image)

settings should be MONOCHROME and 500 DPI – this will export a image with white traces.

Make sure the color mode is set to greyscale: image > mode > greyscale

then export Dimenson layer for milling the outside of the board

Remember: the Modela cuts out the DARK and leaves white!

Correction! It should be both the top and pads layer.

just type in

~$ fab

… upon trying to make path:

distance 0.800000, 140873 exterior points remain

Segmentation fault (core dumped)

must run as sudo

~$ sudo fab