doing some research for 2.008 instead of freaking out over 6.131 lab

Edit 10/17/2011: Found it! Thanks to Charles.

See explanation of “tilt sensors,” which include both mercury and rolling-ball type ones, here: http://www.ladyada.net/learn/sensors/tilt.html

|

| http://www.adafruit.com/products/173 |

Cost: $2.00.

(octopart search: http://octopart.com/partsearch/#search/requestData&q=tilt+switch&rangedfilters%5Bavg_price%5D%5Bmin%5D=0.54&rangedfilters%5Bavg_price%5D%5Bmax%5D=2 can maybe get it for $1)

http://smparts.com/-Switches-Rolling-ball-switches-%28AT%29/c0_2_561/index.html — but no prices listed, hah.

Hmm. So I know there was at least one previous design in 2.008 that used these switches. They put two on each side (top and bottom), facing outwards. Then, when the yo-yo spun, both switches would contact (and presumably switch on LEDs). Apparently they had issues with the thermoform shrinking and squeezing the ball switch and preventing it from switching though. All in all, I’m a bit iffy about these rolling ball switches. There’s no way to adjust their sensitivity (although I guess regardless PoV yoyo requires a microcontroller anyway, but the less pin-count the better), so what if it switches on when the the switches are rotated to (left right) and the yo-yo is slightly tilted? We’d be stuck with 100 useless switches.

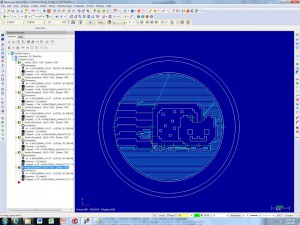

I like Paulina Mustafa’s design of a flexure switch, she was prototyping this at MITERS (but I can’t find a blog for her). Looks sort of a like a ying-yang design, and the tips are flung outward and make contact with the sides when the yo-yo is spun. She’s using copper-tape, but I think something like conductive glue would be easier to apply.

http://www.instructables.com/id/Conductive-Glue-And-Conductive-Thread-Make-an-LED/step1/Make-Conductive-Glue-Conductive-Paint-and-Conduc/

=====

Earlier Research

via

http://www.helifreak.com/showthread.php?t=33567 “DIY Night Blades”

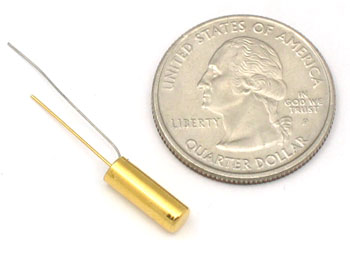

centrifugal switches:

http://www.atomicmods.com/Categories/Tutorial-1-28-Mini-Z-Rim-Light-Installation.aspx

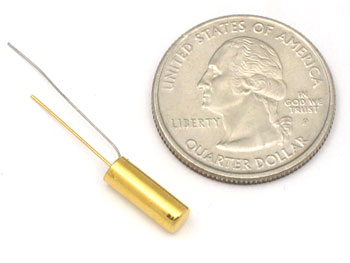

(spring inside a brass tube)

The batteries are wired in series with the LED and the centrifugal switch. The centrifugal switch is simply a tiny spring inside a brass tube. When you accelerate, the spring swings to the outside and makes contact with the brass tube turning on the lights. It is really quite simple and very reliable. This also makes the batteries last a long time since they are only on while you are driving and you will never forget to turn them off.

types of switches and design of switch contacts (including mercury switch aka “tilt switch”): http://www.allaboutcircuits.com/vol_4/chpt_4/1.html

quora question

http://www.quora.com/Mechanical-Engineering/What-centrifugal-switches-are-suitable-for-use-in-a-yo-yo

still failing to find suppliers o.o

mercury switch:

http://mondo-technology.com/yoyo.html

paperclip style:

http://www.make-digital.com/make/vol22?pg=115#pg117