trip to nyc / visit adafruit industries / meet founder of hackaday and talk to ladyada herself!

10 am: depart

2 pm: arrive

|

| left to right: charles, cynthia, and hanna |

|

| arrive in CHINA wait sorry flushing district of New York City |

|

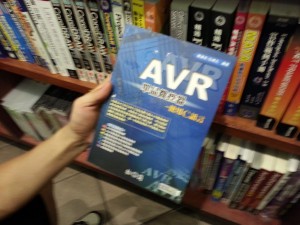

| look what we found in chinatown! an AVR manual IN CHINESE. @___@ |

|

| we ate at Taste of Shanghai on prince street. delicciousss |

|

| Cynthia sketches ladyada chibi! Ladyada was super happy about this when she got it. |

|

| this picture from Charles! Not mine! |

|

| We arrive! |

|

| The magical workings of adafruit heavy metal industries. Err. Adafruit industries. |

|

| $150k+ pick and place machine! IT IS SO SHINY. Apparently it is or is a relative of the ones Samsung uses to manufacture phones, and that this is something Foxconn / Apple would never do, sell you the machines that make machines at a conference |

|

| Assembly station! At adafruit industries they do it by product and not as a procedural task with multiple people per product. The guy is Philip Torrone, founder of hackaday and editor at large at MAKE magazine while he works with adafruit on everything awesome. |

|

| IT’S BINS OF AWESOME BADGES. |

|

| The ladyada shrine 🙂 |

|

| Hydraulic wooden arm spotted! d’aww |

|

| And finally, on the air on ask-an-engineer! We are sitting in the background, as Charles is the main guest (we sort of surprise showed up). Left: Phil; Middle: Ladyada; Right: Charles |

The episode is archived at

http://www.adafruit.com/blog/2013/07/14/ask-an-engineer-references-equals-zero-by-charles-guan/ and

http://www.adafruit.com/blog/2013/07/13/show-and-tell-7132013-e-ink-badges-flora-coats-laser-asteroids-twitter-api-neopixel-code-and-on-air-notifier/

Phil and Ladyada were amazingly open about everything we could ever possibly want to know. I learned that:

- adafruit industries took on no outside investment and was entirely bootstrapped

- it started in just one apartment, then two apartments, and finally they moved to a warehouse

- their first pick ‘n place was picked because it was the only one that fit through their apartment door, and was $35k. they are now donating this to nycresistor with the condition that no questions come their way about how to use it or anything

- after 8 years, they are at 50 employees, 1/3 in shipping, and at 10-15 million dollars in revenue and they are tripling every year.

- They wrote their barcode/shipping software in python and ship ~1000 packages a day. The software notifies the buyer and charges their credit card when items ship

- In fact, they are the largest shipper in lower Manhattan.

- they grew specifically so that ladyada could do all the engineering, and it sounds like they have a few consultants from around the world that help with the engineering but ladyada essentially solo beasts all the products (it sounded like)

- they chose to keep all manufacturing in house instead of outsourced

- they used a black and decker IR oven, equipped with arduino, for reflow for a long time. In the new space, with the real reflow oven and new pick ‘n place, they are finally able to keep up with demand

- Their latest video show has 3 year-olds making lemon batteries o____O Each 2-3 minute video takes over 80 hours to produce. Phil is the one manipulating the giant plushie LEDs / figures under the table

- they are thinking about adding translations to learn.adafruit.com, hopefully crowdsourced, as there is a lot of demand from germany, japan, china, and italy

- adafruit.com gets about 11 million visits (either daily or monthly) after 8 years of relentless quality documentation

- the new move from docuwiki to their own system has cut down documentation time by about a third

- but each tutorial still takes anywhere from 6 hours to 2 days

- Their PCB stencils are done by hand. They found that people can do it better when trained and get over 99% yield, such that they almost think they don’t need an optical checker

- Testing rigs for circuitboards! Ladyada actually designs products with testing in mind

- They worked with companies like Eagle to make girl scout/boy scout-esque badges, and Eagle was very happy about it

- They helped Jay Silver with MakeyMakey, who really just needed encouragement that a market exists

- Ladyada did not market ressearch nor business plan. She believed in the product strongly enough that she created a market / demand for it. Execute.

- ladyada reminisced about her time at MITERS and how it used to very much by Tim Anderson’s shop, and also about her Bridgeport mill which is still in active use at MITERS

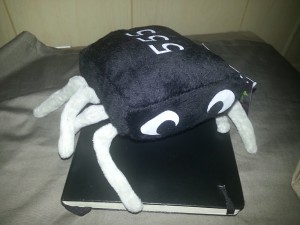

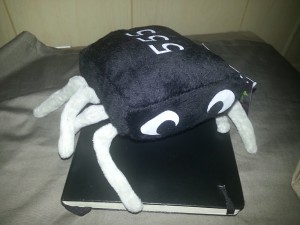

ALSO. I GOT A 555 PLUSHIE. d’awwwww it is an octopod ^__^ heart cousin of hexapods

And a final note on fail.

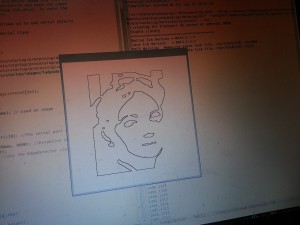

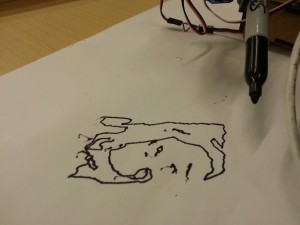

I wanted to draw ladyada’s face with our robot arm but sadly we were not at a stage to make a recognizable drawing and I think ladyada was just like, WTF. ;__; SORRY LADYADA one day we will draw better faces with our el cheapo 9g miniservos and then give you a portrait. we probably should have stuck to the adafruit logo or something.

|

| edge detected from the WIRED magazine cover |

|

| draw out… yea… it does not resemble ladyada at all x___x |

http://youtu.be/q73vKiPvaPA?t=59s

Ah well. So it goes, so it goes.

That’s all for tonight folks! Getting ready to teach Intro to Robot Arms, class #2, in a few hours (for MIT HSSP. Let me know if you all have any questions.

Oh, an easy one — I don’t know how this came about. I think Charles emailed Ladyada saying he would be in NYC and wanted to visit, and he was then invited as a guest onto the show. He was going to by in NYC for a mikuvan trip including us, so we tagged along to visit adafruit industries. All quite strange and befuddling.